Inventor Advanced – Sheet Metal Design

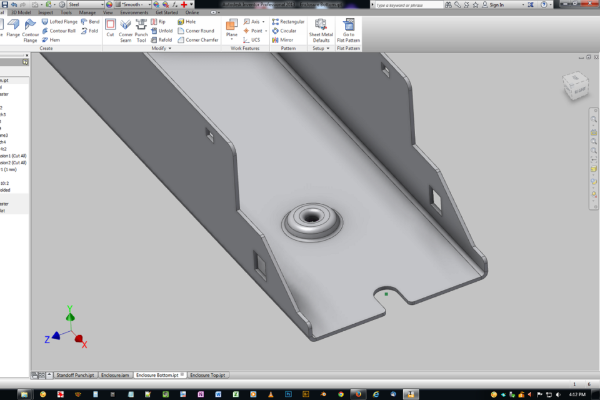

This course will teach the user how to create and document sheet metal parts inside of Autodesk Inventor. The course covers everything from basic sheet metal features to complex shapes and design techniques. The structure of the course follows the typical stages of using Inventor which is to create sheet metal parts, edit them, generate flat patterns, and document the designs in the drawings.

The primary objective of this course is to enable users to understand the basic features of Sheet Metal, what it consist, what it needs, what it delivers and how to create sheet metals base plate, bending, flanges and flat patterns.

PREREQUISITES

Knowledge of 3D Modeling using Autodesk Inventor

TARGET GROUP

Experienced Inventor user with basic hands-on Sheet Metal knowledges

Duration

3 Days (21 hours)

Course Achievement

Certificate of Completion by Autodesk

At the end of the course, you will be able to:

• Understand the Inventor Sheet Metal User Interfaces & workflow

• Create Base Plate, Flanges & bending’s

• Editing Flanges & Bends

• Understands Sheet Metal parameters

• Creating Punch Holes

• Generate Flat Patterns

• Creating Rips

• Folding and Unfolding

• Converting Solid Bodies in to Sheet Metals

• Managing & Creating Sheet Metal Rules

• Creating Sheet Metal Drawings & Annotations Required

BENEFITS OF Inventor Advanced – Sheet Metal Design TRAINING

Proficiency in Sheet Metal Modeling

Material Optimization

Familiarity with Advanced Tools

Collaboration and Communication

View Course Content

DAY 1

- Sheet Metal Concepts

- Sheet Metal Terminology

- Sheet Metal Environment

- Sheet Metal Design Process

- Applying Existing Sheet Metal Defaults

- Creating a face as a Base Feature

- Creating a Contour Flange as a Base Feature

- Creating a Contour Roll as a Base Feature

- Sheet Metal Parameters

- Bend relief Shapes

- Faces as Secondary features

- Contour Flanges as Secondary Features

- Contour Rolls as Secondary Features

DAY 2

- Creating Flanges

- Corner Relief Options

- Hems

- Folds

- Bends

- Creating Corner Rounds

- Creating Corner Chamfers

- Creating cut Features

- Creating Straight Holes

- Using Punch Tool

- Creating a Punch Tool

- Cuts Using Surfaces

DAY 3

- Creating Corner Seams and Miters

- Converting Corner Rips

- Converting Corner Seams and Bends

- Creating Flat Patterns

- Orienting Flat Patterns

- Punch Representations

- Bend Angle

- Flat Patterns Cleanup

- Exporting to DXF/DWG

- Lofted Flange

- Rip

- Unfold and Refold

- Sheet Metal Terminology

- Creating Sheet Metal Drawings

- Bend & Punch Notes

- Bend Tables

- Punch Tables

- Bend Order

- Cosmetic Centerlines

- Converting Solid Models to Sheet Metal

- Non-Ruled Surface